In today's globalized and competitive business environment, the supplier

selection process has become a critical activity for organizations across various

industries. The selection of appropriate suppliers directly impacts an organization's ability to maintain a reliable supply chain, control costs, ensure product quality, foster innovation, and achieve overall competitive advantage

[3][4]. A well-defined and executed supplier selection process enables

businesses to minimize risks, maximize value, and build long-term, mutually

beneficial relationships with their supply base. This paper aims to explore the key

criteria for evaluating and selecting suppliers, providing a framework for

organizations to make informed decisions aligned with their strategic objectives.

The Supplier Selection Process

The supplier selection process is a systematic approach that involves several key

stages:

1. Identifying Business Needs: The first step involves clearly defining the

organization's requirements, including the specific products or services

needed, quantity, quality standards, delivery schedules, and any other

relevant specifications.

2. Listing Potential Suppliers: This stage involves identifying potential

suppliers through various sources such as industry networks, online

directories, trade publications, referrals, and market research

3. Determining Selection Criteria: Establishing a comprehensive set of

criteria to evaluate and compare potential suppliers is crucial for making

objective and informed decisions

4. Request for Information/Proposal (RFI/RFP): Qualified suppliers are

then invited to submit RFI/RFPs, providing detailed information about their

capabilities, pricing, quality control processes, and other relevant factors

5. Evaluating and Selecting Suppliers: The evaluation process involves

assessing the submitted proposals against the pre-defined criteria,

conducting site visits or audits if necessary, and shortlisting the most

promising suppliers

6. Negotiating and Finalizing Agreements: The final stage involves

negotiating contract terms, pricing, and service level agreements with the

selected supplier(s)

7. Supplier Relationship Management: Ongoing monitoring of supplier

performance, communication, and collaboration to ensure continuous

improvement and value creation

Key Supplier Selection Criteria

The specific criteria used for supplier selection may vary depending on the

industry, the nature of the product or service being sourced, and the

organization's strategic priorities. However, some core elements should always

be considered :

1. Quality and Safety of Products/Services: This is a fundamental and

non-negotiable requirement. The supplier's ability to consistently meet or

exceed the required quality standards is paramount. Evaluation should

include assessment of certifications (e.g., ISO 9001), quality control

processes, defect rates, and performance history.

2. Cost and Price Structure: While cost should not be the sole determinant,

it remains a significant factor. Organizations should consider the total cost

of ownership, including purchase price, transportation costs, discounts,

payment terms, and potential long-term costs.

3. Delivery and Reliability: Timely and reliable delivery is crucial for

maintaining a smooth supply chain and meeting customer demands.

Factors to consider include the supplier's delivery performance history,

lead times, logistics capabilities, and ability to handle disruptions

4. Financial Stability: Assessing the supplier's financial health is essential

to ensure their long-term viability and ability to meet commitments.

Organizations should review financial statements, credit ratings, and other

relevant indicators to evaluate the supplier's financial stability.

5. Capacity and Scalability: The supplier's capacity to meet current and

future demand is an important consideration , Organizations should

assess the supplier's production capacity, equipment, workforce, and

ability to scale operations as needed.

6. Technology and Innovation: In today's rapidly evolving business

landscape, a supplier's technological capabilities and commitment to

innovation can provide a significant competitive advantage. Assessment

should include their use of advanced technologies, R&D investments, and

ability to develop cutting-edge solutions.

7. Ethical and Environmental Practices: Increasingly, organizations are

considering ethical and environmental factors in their supplier selection

process. This includes assessing the supplier's adherence to fair labor

practices, environmental sustainability initiatives, and commitment to

social responsibility.

8. Communication and Collaboration: Effective communication and

collaboration are essential for building strong supplier relationships.

Organizations should evaluate the supplier's communication systems,

responsiveness, and willingness to collaborate on problem-solving and

continuous improvement initiatives.

9. Risk Management and Preparedness: Suppliers should have robust risk

management strategies in place to mitigate potential disruptions to the

supply chain, This includes assessing their ability to handle unforeseen

events such as natural disasters, economic downturns, or geopolitical

instability.

10. Flexibility: The supplier's ability to adapt to changing business needs and

unexpected order changes.

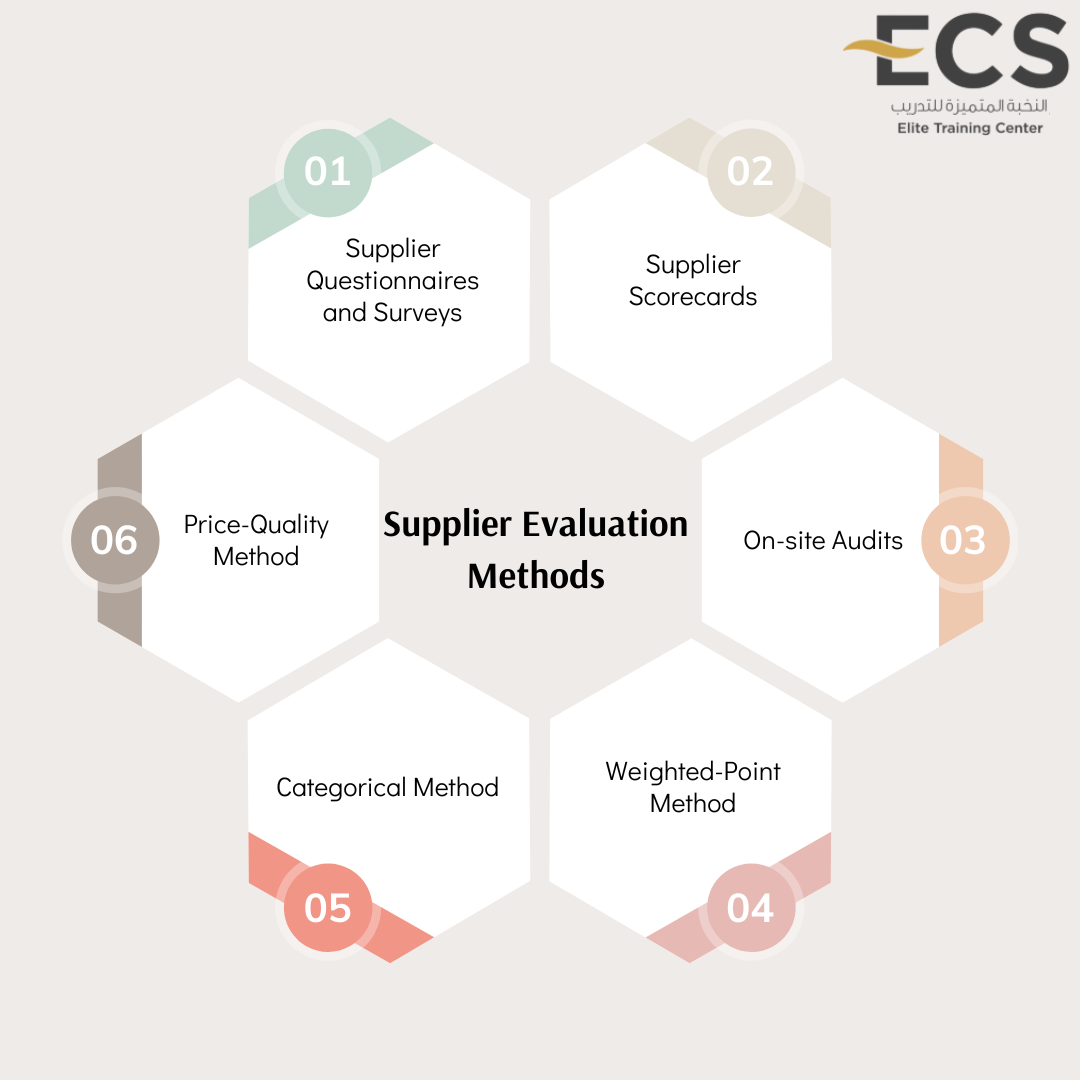

Supplier Evaluation Methods

Various methods can be employed to evaluate suppliers against the defined

criteria:

1. Supplier Questionnaires and Surveys: Standardized questionnaires are

used to gather information from potential suppliers on various evaluation

criteria.

2. Supplier Scorecards: Scorecards provide an objective framework for

evaluating and ranking suppliers based on key performance indicators

(KPIs) such as quality, cost, delivery, and service

3. On-site Audits: Visiting the supplier's premises to conduct audits can

provide valuable insights into their operations, quality control processes,

and adherence to standards.

4. Weighted-Point Method: This quantitative approach involves scoring

suppliers based on criteria weighted according to their importance.

5. Categorical Method: This uncomplicated method uses categorical terms

(e.g., "good," "neutral," "poor") to rate supplier performance against various attributes.

6. Price-Quality Method: This method combines both quantitative and

qualitative evaluation, where companies evaluate both pricing and quality

together to select the supplier that fits both evaluation criteria.

The Importance of Supplier Relationship Management (SRM)

Supplier selection is not a one-time event but rather the beginning of an ongoing

relationship. Effective Supplier Relationship Management (SRM) is crucial for

maximizing the value derived from these relationships. SRM involves developing

trust, fostering open communication, and collaborating with key suppliers to drive

innovation, improve performance, and mitigate risks. By investing in SRM,

organizations can create a competitive advantage through a resilient and high-

performing supply chain.

Challenges in Supplier Selection

Despite the importance of supplier selection, organizations often face several

challenges:

Overemphasis on cost reduction: Focusing solely on price can lead to

neglecting other critical factors such as quality, reliability, and innovation.

Lack of specific SRM competencies: Insufficient skills and knowledge in

managing supplier relationships can hinder effective collaboration and

value creation.

Insufficient alignment: A lack of alignment between business,

procurement, and supplier objectives can lead to conflicts and missed

opportunities.

Information asymmetry: Difficulty in obtaining accurate and reliable

information about potential suppliers can make it challenging to make

informed decisions.

Dynamic market conditions: Rapid changes in market conditions,

technology, and regulations can make it difficult to assess long-term

supplier viability .

Conclusion

Supplier selection is a critical process that significantly impacts an organization's

success, By establishing clear selection criteria, employing appropriate

evaluation methods, and investing in supplier relationship management,

businesses can build strong, resilient, and value-driven supply chains. In addition

to traditional factors like quality, cost, and delivery, organizations must also

consider ethical, environmental, and innovative capabilities when selecting

suppliers [3][23]. Embracing a holistic and strategic approach to supplier

selection enables organizations to mitigate risks, improve performance, and

achieve sustainable competitive advantage.

References

1. Supplier Selection Criteria and Methods in Supply Chains: A Review -

Semantic Scholar

2. Exploring the importance of different supplier selection criteria -

ResearchGate

3. Understanding the Basics of Supplier Selection - NetNada

4. Key Supplier Selection Criteria Every Procurement Executive Should

Know

5. Supplier evaluation and selection: Criteria and methods - Lawcode

6. Supplier Selection Process: A Quick Guide | SafetyCulture

7. How to Perfect Your Supplier Selection Process in 5 Steps - DeepStream

8. Supplier Selection: Choose the Right Supplier | SafetyCulture

9. 5 Steps to Supplier Selection - Transformance Advisors

10. Supplier Evaluation - How to Evaluate Suppliers - CIPS

11. (PDF) Supplier Relationship Management: Strategies for Enhancing

Collaboration and Performance - ResearchGate

12. Supplier Relationship Management and Organizational Performance: A

Focus on Public Procurement - Research leap

13. Criteria for supplier selection: A literature review - ResearchGate

14. Vendor & Supplier Selection Process: Criteria & Best Practices | Infosys

BPM

15. Supplier Selection Criteria — The Ultimate Guide - Procurement Tactics

16. The Complete Guide to Vendor Selection Process - Tipalti

17. What is the Supplier Selection Process | CIPS

18. Five Effective Methods for Selecting Suppliers in the Oil and Gas Industry

19. 6 Methods for Effective Supplier Evaluation - Veridion

20. Supplier Evaluation: The Methods and Benefits - TenderBoard

eProcurement Platform

21. Supplier Relationship Management - CBS Research Portal

22. Supplier Relationship Management How key suppliers drive your

company's competitive advantage - Pwc.nl

23. Assessing the Best Supplier Selection Criteria in Supply Chain

Management During the COVID-19 Pandemic - PMC

Elite Training Center:

www.ellite-t-s.com

Date: 19/10/2025